Design for Manufacturing (DFM): Key Strategies for Successful Product Launch

Understanding Design for Manufacturing (DFM)

Design for Manufacturing (DFM) is a critical approach in product development that ensures products are designed with the manufacturing process in mind. By integrating DFM early in the design phase, companies can significantly reduce production costs and time-to-market while improving product quality. This strategy emphasizes designing products that are easy to manufacture, assemble, and test.

In today’s competitive market, DFM is more crucial than ever. It involves collaboration between design engineers and manufacturing teams to identify potential production challenges before they occur. This proactive approach not only streamlines the manufacturing process but also enhances product innovation and sustainability.

Key Strategies for Implementing DFM

Collaborative Design Process

One of the primary strategies in DFM is fostering a collaborative environment between design and manufacturing teams. By working together from the beginning, these teams can share insights and feedback that lead to more practical and efficient designs. This collaboration helps in identifying potential production issues that might arise, allowing for adjustments before manufacturing begins.

Simplification of Product Design

Simplifying product designs is another effective DFM strategy. By reducing the number of components and using standard parts wherever possible, companies can lower manufacturing costs and minimize assembly errors. Simplified designs also facilitate automation, which can further enhance production efficiency.

Materials and Process Selection

Choosing the Right Materials

Selecting appropriate materials plays a pivotal role in DFM. The right materials should not only meet the product's functional requirements but also be easy to work with during manufacturing. Considerations such as material cost, availability, and compatibility with manufacturing processes are essential in making informed decisions.

Optimizing Manufacturing Processes

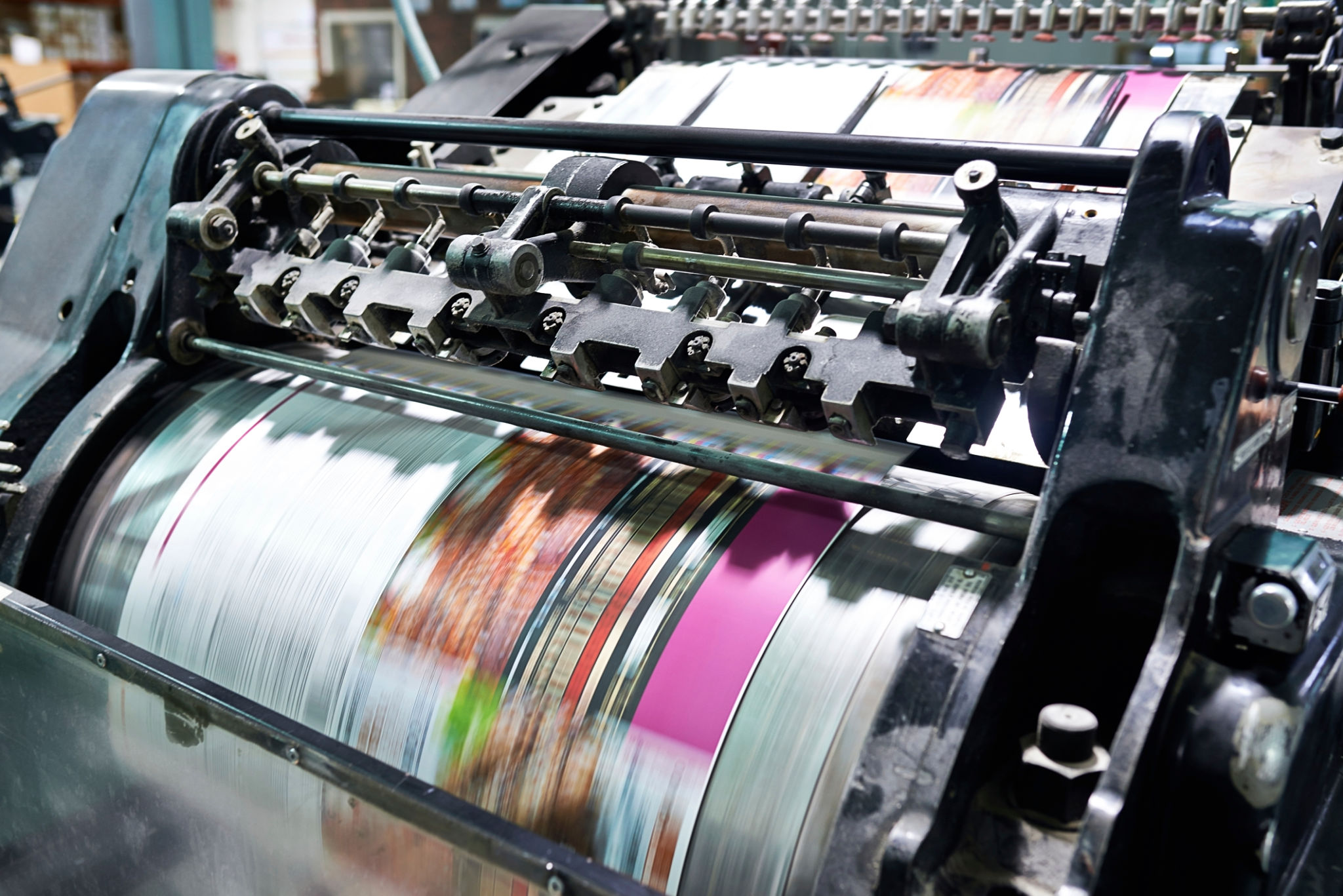

Aligning product design with suitable manufacturing processes is crucial for achieving high-quality outcomes. Companies should evaluate various manufacturing techniques to determine the most efficient method for producing their products. This includes considering advancements in technology and machinery that could offer improved precision and speed.

The Benefits of DFM in Product Launch

Integrating DFM into the product development cycle offers numerous benefits that contribute to a successful product launch. These include:

- Reduced Production Costs: By designing with manufacturing efficiency in mind, companies can minimize waste and optimize resource use.

- Improved Product Quality: Early identification of potential design flaws leads to higher-quality products with fewer defects.

- Faster Time-to-Market: Streamlined processes and reduced production delays help companies launch products more quickly.

Overall, Design for Manufacturing is an essential practice for any company looking to enhance its product development process. By adopting DFM strategies, businesses can achieve greater operational efficiency, increase profitability, and deliver superior products to the market.